MARKET: Steel Industry

SAC: Germany

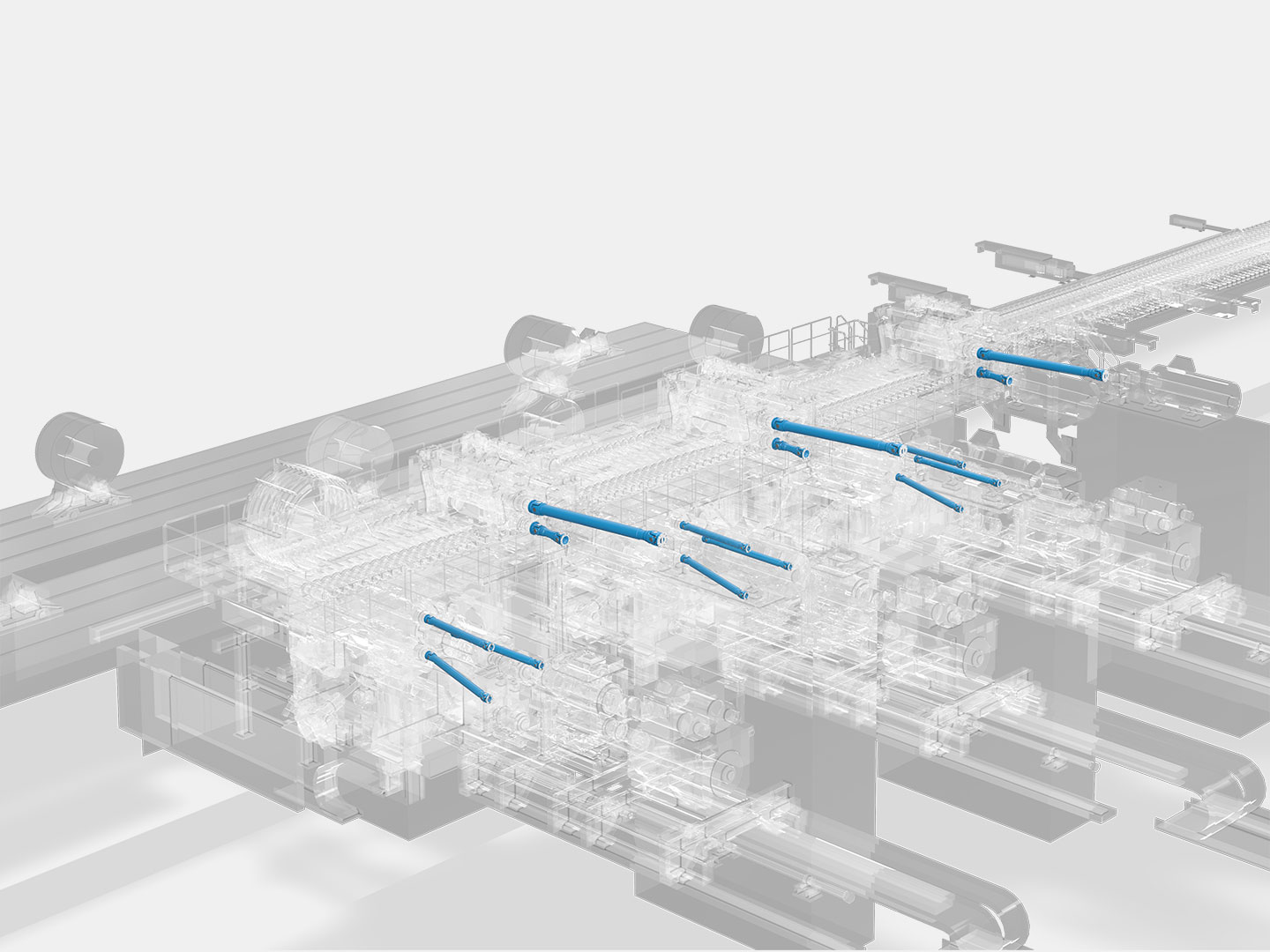

THE PROJECT: Down Coiler

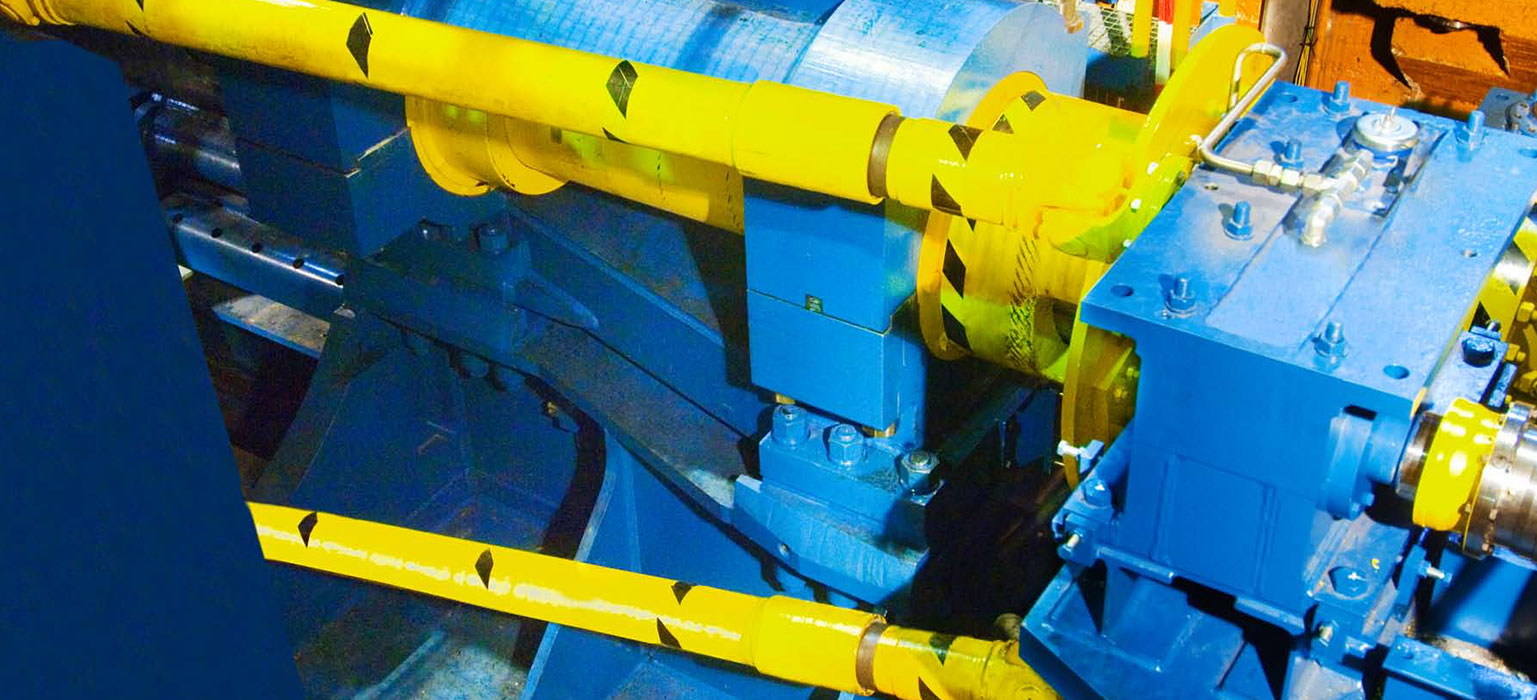

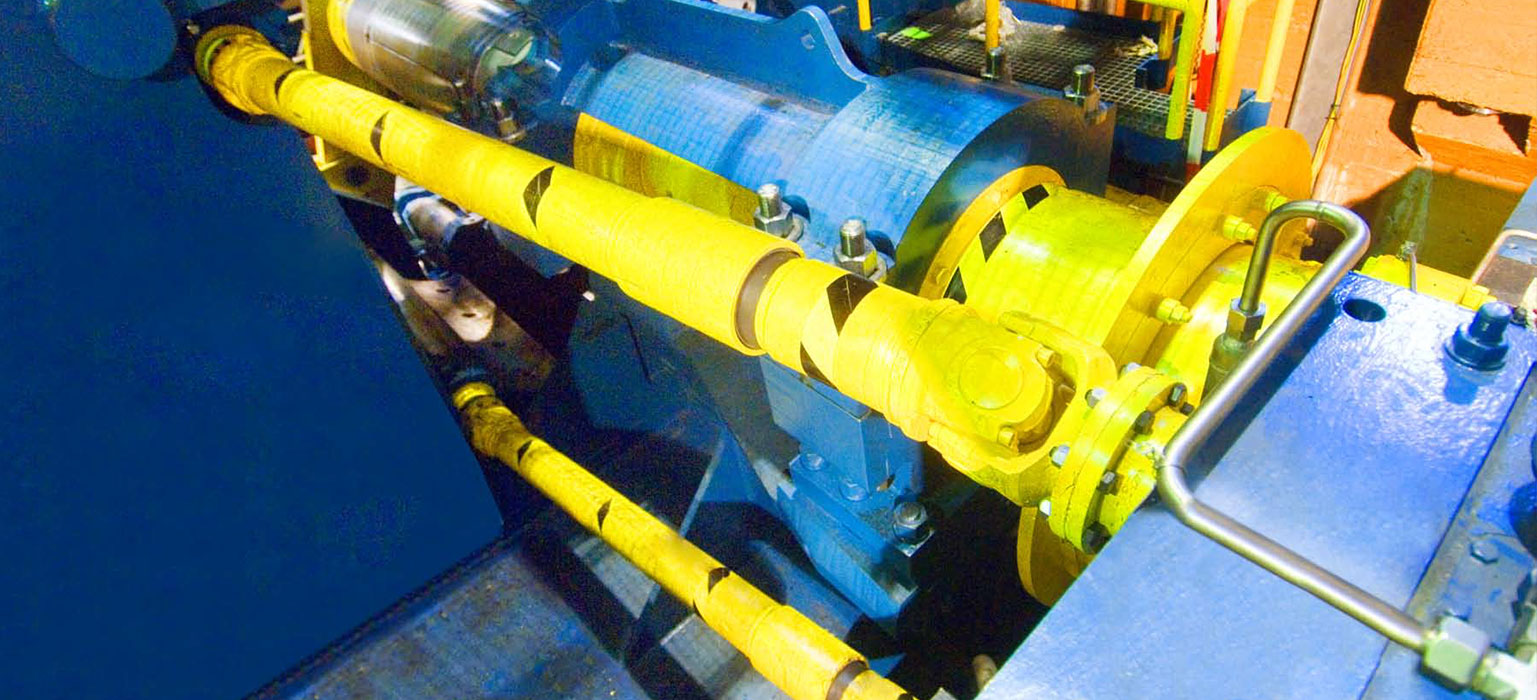

Familiar with our long-standing experience in this industry and with this application, the customer needed to equip a down coiler working in tough conditions, where heat and impact resistance were crucial, as well as a large operating angle and high-speed operation.

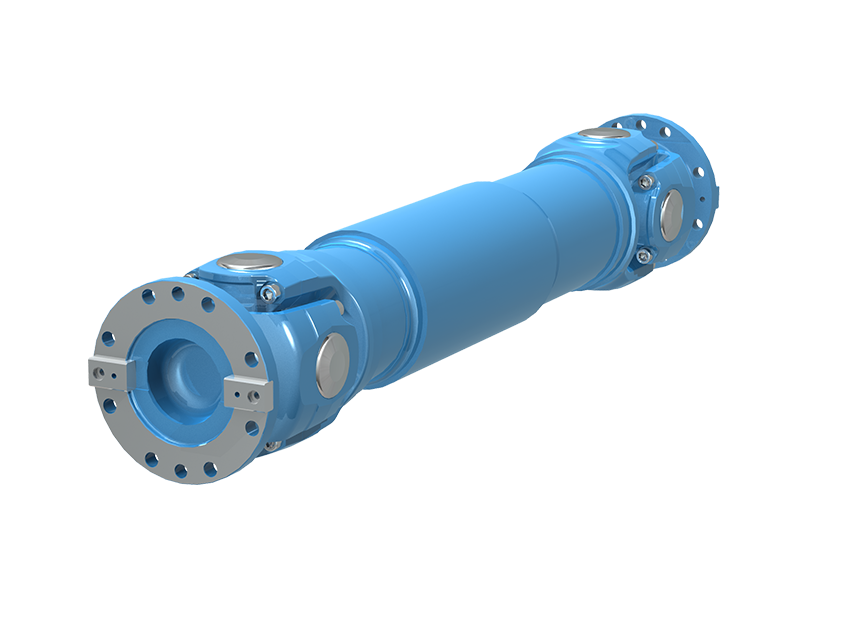

Based on our standard 392 driveshaft series, we implemented a number of customized features to respond to the specific customer demands. With over 1,000 units installed worldwide in the last 20 years, our experience enables us to pinpoint the solution quickly and effectively. Using valuable feedback from end-users and partnering with the world’s leading manufacturers, we have been able to develop the best answers.

In this case, the wrapper roll shafts featured:

Such a combination of tailored solutions comes from our expertise and the experience we have gathered over the years. Each feature is implemented to resolve a problem common to many such applications.

A few key characteristics of the three wrapper roll shafts we delivered:

The result is a premium quality product ensuring longer operating service, less maintenance, and superior performance.

In the long term, a cost-effective answer for the steel mill.

The result was a supply of

down coiler equipped with 3 wrapper roll shafts

years of experience developing these shafts based on end-user feedback and partnership with a leading manufacturer

similar shafts delivered/installed globally