MARKET: Mining

SAC: South America

THE PROJECT: Automatic Tensioner System

MARKET: Mining

SAC: South America

THE PROJECT: Automatic Tensioner System

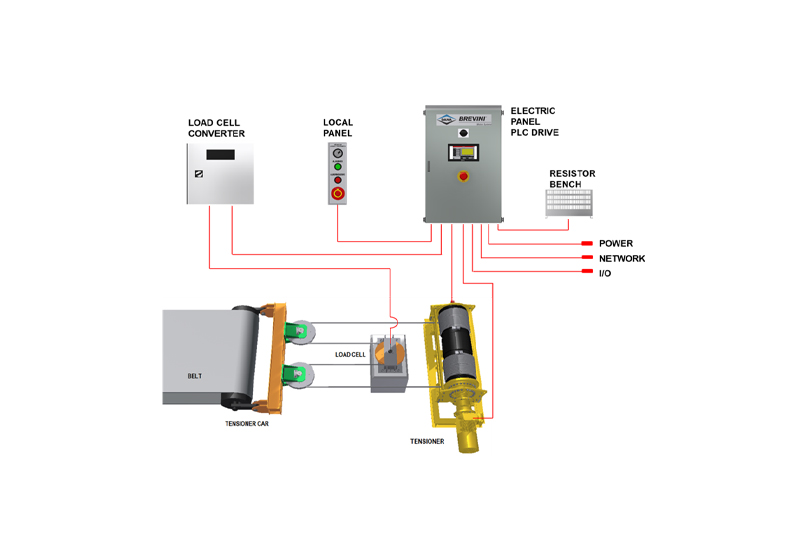

Provide a solution to improve the performance and reliability of a counterweight belt conveyor mining application in South America. The solution needs to

The Dana SAC serving the South American market leveraged their experience and proposed Dana’s Automatic Tensioner Systems (ATS) for belt conveyors already produced and in-use for the mining industry. The Dana SAC team replaced the existing counterweight block and tower structure with a total of 10 Dana ATS solutions, each with either a 40-ton (5) or 60-ton (5) capacity.

In addition to the new ATS solution, an automated electric winch and Dana-developed custom belt-tensioning software provided a truly customized system. With this new solution in place, correct belt tensioning was available under any running conditions.

Dana ATS features:

The Dana ATS solution ensures maximum safety during installation, operation, and maintenance, due to its ease of access. Belt lifespan is increased and compared to the counterweight block and tower structure, capital expenditure is lower for new installation, as well as ongoing operating costs.

The unique approach to this common problem yields safety, reliability, maintenance, and cost benefits that can benefit any mining site, as well as other markets moving material along a conveyor system.

An overview of the key numbers related to the project:

Dana ATS - Automatic Tensioner Systems

60-ton capacity units

40-ton capacity units

Production plant - Limeira (São Paulo)