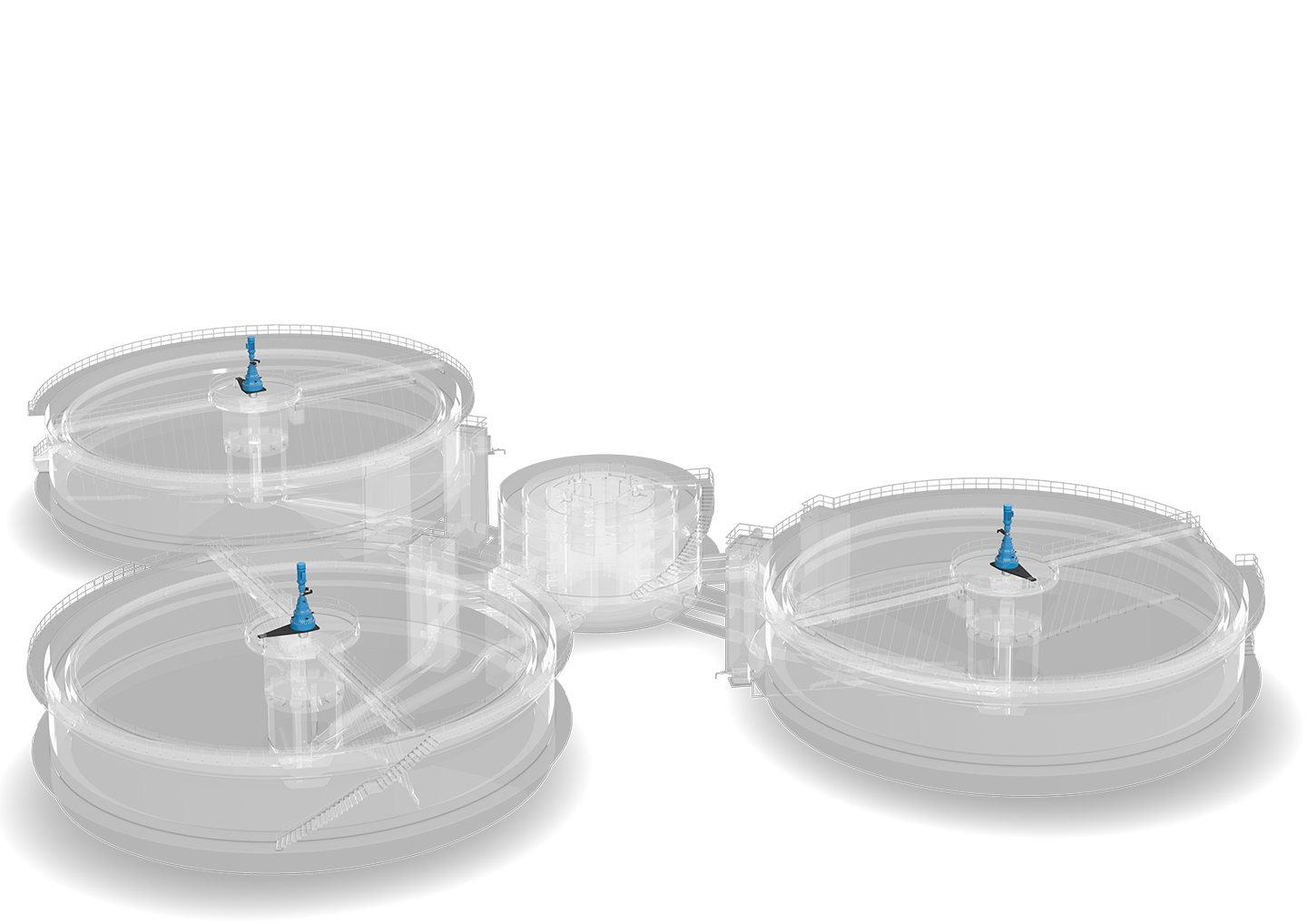

Clarifier-Crystallizer-Thickener

Clarifier

The principal task of a clarifier or juicer is to separate the solids from the sugar cane liquid in order to minimize impurities and thereby obtain the purest juice possible. Juice is heated to help kill natural enzymes; flocculants are added as well as lime which brings the juice to a neutral pH value. While the impurities precipitate to the bottom of the clarifier, the clear juice flows off the top part of the vessel towards the next crystallization phase.

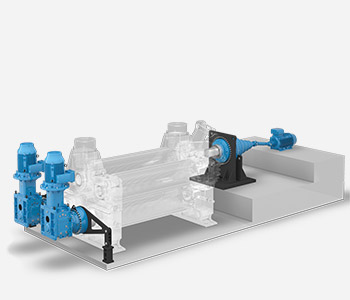

Vertical crystallizers

By means of an artificial process in a crystallizer, sugar is transformed from its liquid form into a solid crystallized structure. The most efficient solution is a vertical crystallizer where the massecuite (raw sugar crystals mixed together with molasses) flows vertically from top to bottom. Vertical crystallizers are found in both the beet and cane sugar industries. Separation of the molasses from the sugar crystals takes place in a centrifuge. On both applications, the gearboxes allow for slow turning of the rake.

Thickeners

Thickeners are predominantly found in mining or the cement industry, where they are used to separate solids from the fluid. Once the solids reach anything up to a 50% density, they are discharged from the thickener by means of a pump. The clear liquid overflows at the top of the thickener and is pumped away.

- Modular concept

- Extensive ratio range

- Supports torque range up to 2200 kNm

- Increased thermal capacity due to large bevel set

- Spheroidal graphite cast iron housing

- High efficiency

- Diverse low-speed shaft options

- Premium sealing

- Low noise

- IEC flanges up to 355 size

Market related applications

When the sugar cane reaches the sugar mill, it is shredded to break down the fibrous stalks and […]