Compounding

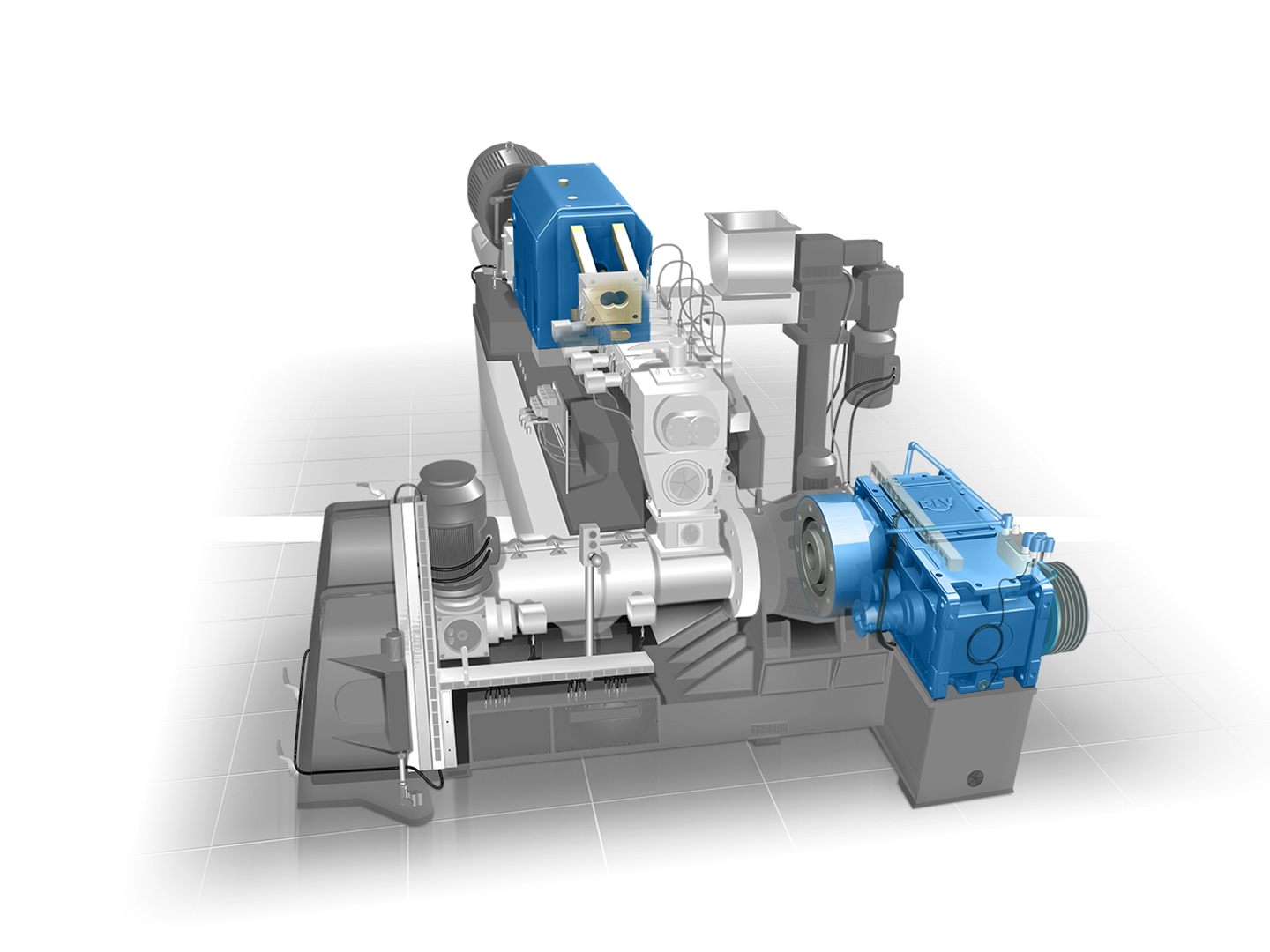

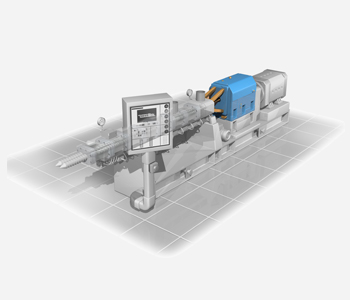

During the compounding process, which mixes basic material with other components, a new substance is formed with different characteristics. Our experience in this application, together with our technical leadership for twin-screw extruder gearboxes with high torque density, and their prove reliability, places Dana at the forefront thanks to the POSITWIN series of twin-screw extruder drives.

MACHINE DETAILS

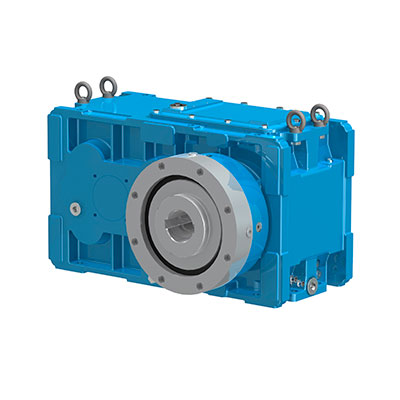

- From 1 to 4 helical stages

- 25 sizes available

- Output torque from 3.000 up to 1.100.000 Nm

- Solid- and hollow output shafts

- Customised output housing and shafts

- High flexibility in combination of the ratios

- Splash- or forced- lubrication, with shaft or motor driven pump

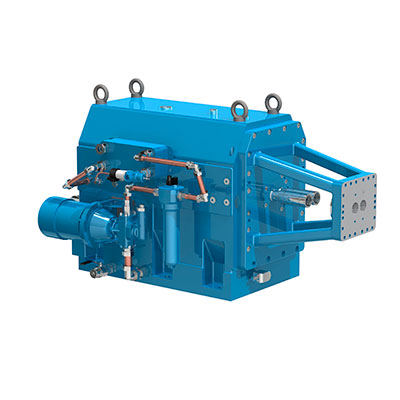

- 1 helical stages reduction

- Center distance from 21mm up to 205 mm

- 30 sizes available

- Output torque from 40 Nm up to 35.000 Nm

- Torque density up to 20 Nm/ mm2

- Splash- or forced- lubrication, with shaft or motor driven pump

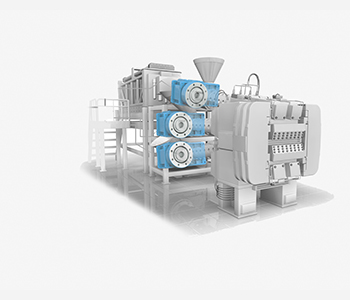

Market related applications

This is a specific manufacturing process during which plastic elements are formed and joined together. In-depth experience in […]

Using our POSIREX drives on the extruder screw, our customers benefit from modular solutions for gearbox and thrust-bearing […]

This is a specific manufacturing process during which plastic elements are formed and joined together. In-depth experience in […]

Using our POSIREX drives on the extruder screw, our customers benefit from modular solutions for gearbox and thrust-bearing […]

This is a specific manufacturing process during which plastic elements are formed and joined together. In-depth experience in […]

Using our POSIREX drives on the extruder screw, our customers benefit from modular solutions for gearbox and thrust-bearing […]

This is a specific manufacturing process during which plastic elements are formed and joined together. In-depth experience in […]