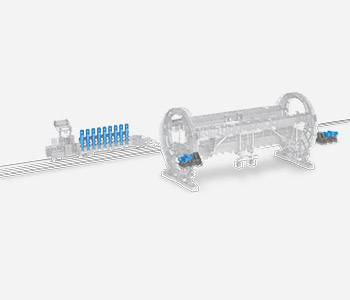

Roller presses

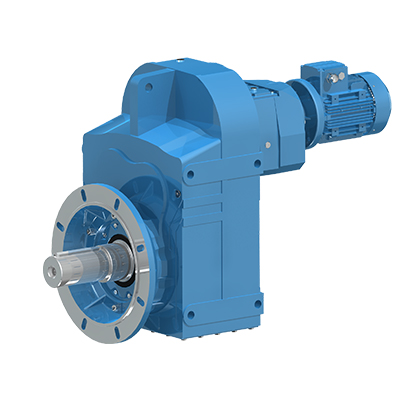

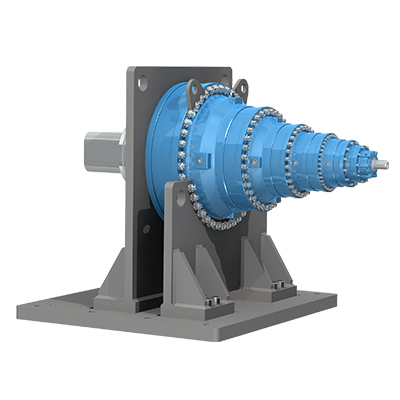

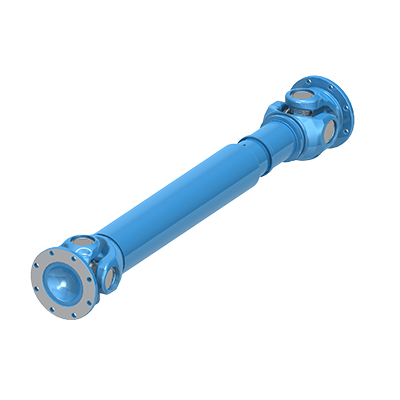

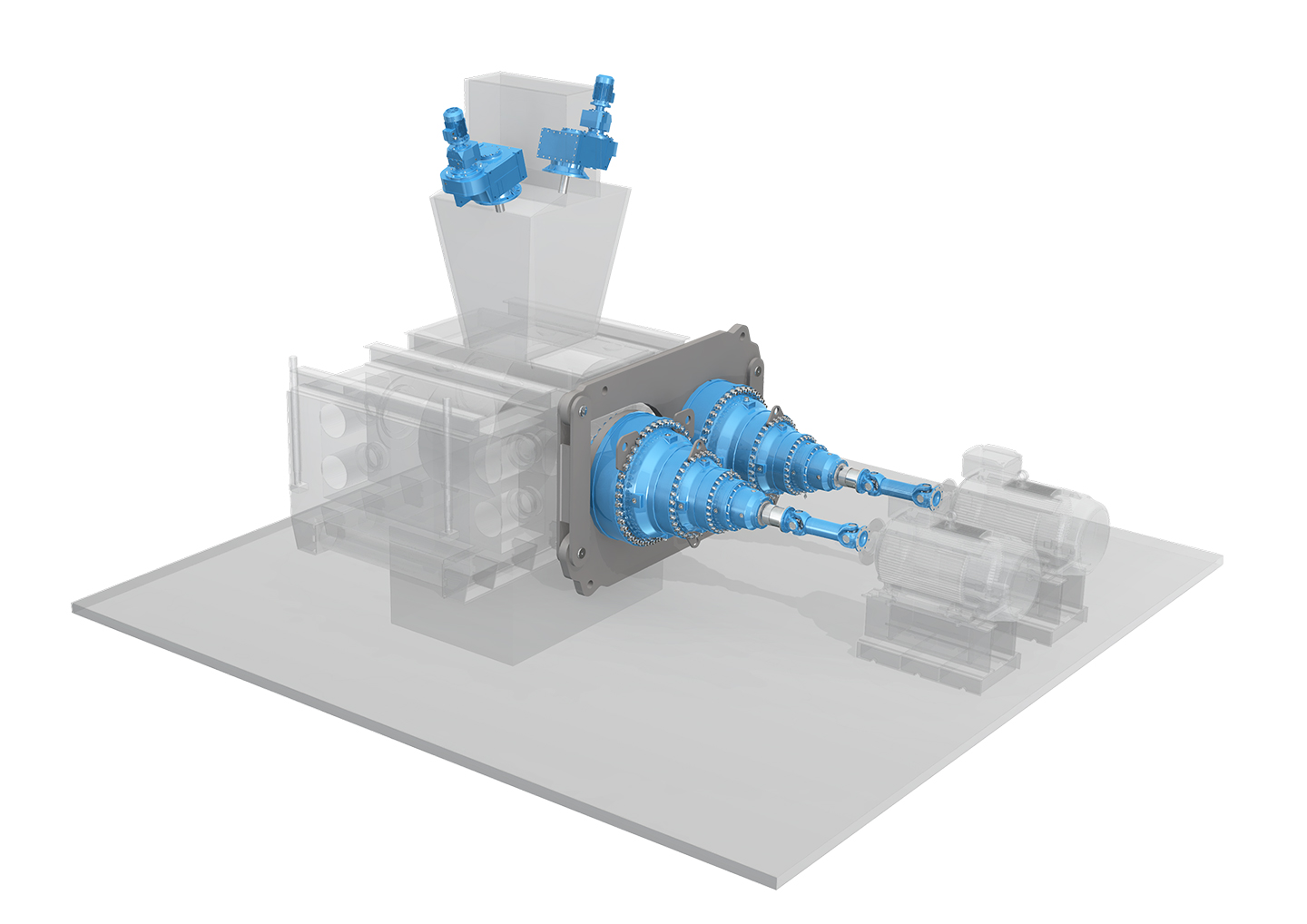

In order to crush ore, roller presses, or high-pressure grinding rolls (HPGR), utilize two counter-rotating rolls – one fixed and one movable. Compared to traditional systems, this design increases stability and efficiency. Roller presses can be used for grinding as well as compacting. The drive power is transferred to the grinding rollers via multistage Brevini® planetary gearboxes mounted on the drive end of the roller shaft using shrink disc coupling or a low-speed flange. Traditional drives above 400 kW are equipped with fluid- or torque-limiter coupling and a cardan shaft. Bulk material is fed through the gap between two rollers, then through a feeding device on top of the machine, which can vary depending on feeding method.

MACHINE DETAILS

- High efficiency

- Diverse low-speed shaft options

- Low noise

- Robust housing made in cast iron GG20-22

- Supports torque range up to 2200 kNm

- Spheroidal graphite cast iron housing

- High efficiency

- Diverse low-speed shaft options

- Premium sealing

- Reliable operation, engineered for harsh conditions

- Low noise

- Special torque arm systems

- Superior bearing life

- High torque capacity

- Maintenance: friendly design with service free option

- Engineered to withstand harsh conditions,proven with a 70-year history on the market

- Designed to minimize total cost of ownership

Market related applications

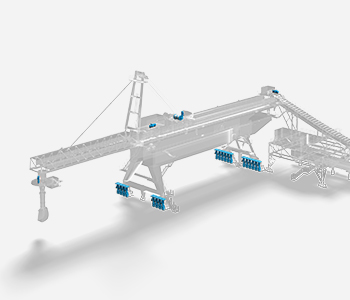

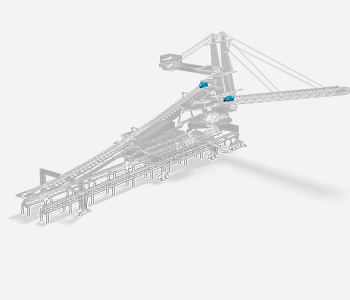

Large-sized equipment used in shipyards to load and unload solid, bulk material such as iron ore, coal, fertilizer, grain, […]

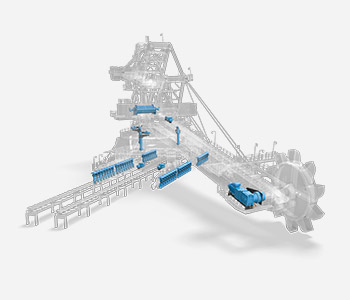

These versatile machines operate as both stacker and reclaimer, stacking material in stockpiles and reclaiming loads with a bucket […]

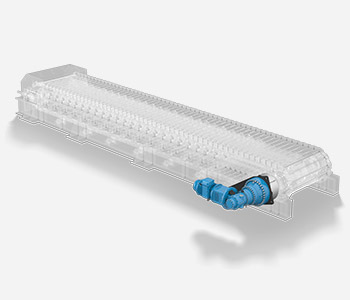

Conveyors are the workhorse of mineral handling, often used in dry processing plants where they play a key […]

Apron feeders are necessary whenever the application requires a uniform flow of dry or moist fractions of rock […]

Wagon tipplers and positioners

Wagon tipplers are used to unload bulk material from wagons, including coal, coke, lignite, iron ore, limestone, dolomite, […]